NEWS

Advantages of extruded aluminum t slot framing

Whether you are assembling a large production line, installing automation equipment, or setting up a workbench for the production line, you may need a metal frame to install robot parts, dispensers, or other automatic assembly equipment. Many factory owners choose the traditional welded steel structure to enhance its strength and durability. However, aluminum extruded frames are becoming more and more popular for several reasons.

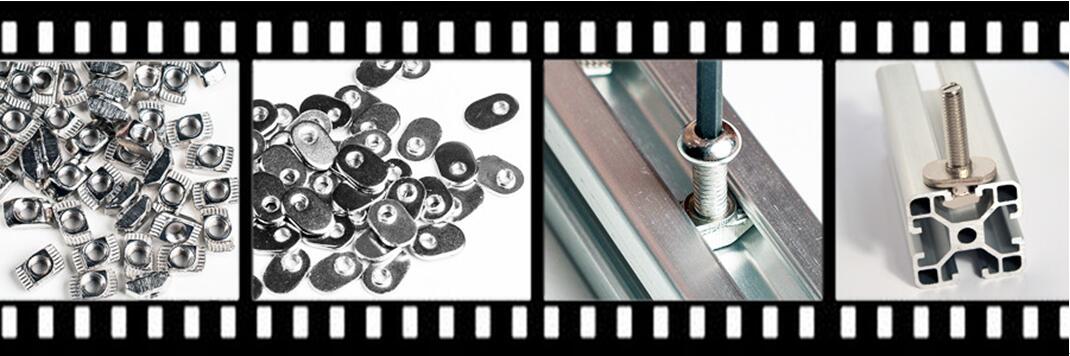

Chalco's extruded aluminum t slot framing is a modular solution consisting of aluminum extrusion profiles and unique T-slot design, as well as a series of special connectors and fasteners, allowing designers or buyers to adjust the structural frame according to their own needs.

1. Wide application range:

Unique decoration, sound insulation, heat preservation, good regeneration, extruded aluminum t slot framing is widely used in the construction field, with the advantages of extrusion molding, good mechanical and physical properties, good thermal conductivity, high specific strength; suitable for rack, bracket, door, industrial automation equipment, factory and office workbench, shelf, container, ladder, etc.

2. Easy to assemble and install:

Modular and multi-functional, without complex design and processing, can quickly build the ideal mechanical equipment cover.

Some people say that steel is cheaper than aluminum in the same unit. But a hidden cost labor force should not be ignored, especially for intensive setting. In the assembly process, you need to hire a professional assembler to put the parts in place, and even you have to hire technical workers (and / or processing facilities) to cut and weld materials, which is more impossible to complete in a short time.

3. Adapt to changes and attractive appearance

The extruded aluminum t slot framing determines the incomparable adaptive performance of T-groove aluminum extrusion frame, and the frame system is more flexible than steel. Parts or parts can be interrupted and disconnected and then reassembled as needed. In addition, the aluminum extruded frame structure can be vernier adjusted to move the connector or fastener a few millimeters here or there for proper installation.

Instead, the steel must be planned as a welded structure before installation, even though each measurement and bolt must be accurately determined in advance. It is difficult to change the position of these steels when they are permanently welded together and drilled into precise holes. Therefore, once the equipment or process changes on the road, the steel structure may not be able to adapt accordingly.

Compared with the steel structure, extruded aluminum t slot framing does not need to be painted, and the steel structure must be coated with protective coating to help slow down the inevitable process. Anodized aluminum extrusions have beautiful appearance and good corrosion resistance.

4. Easy to maintain

Due to the modularity of extruded aluminum t slot framing, when the structure is damaged in the production process, the parts can be updated easily and quickly. However, if you change to another material and take the steel structure, first you have to stop production to repair it. You can imagine the maintenance process: reduce damaged parts and replace them with new ones; the machine must stop working during the whole maintenance process.

NEWS

- What's the T slot aluminum profiles

- Industrial T slot aluminum extrusions

- How to improve the production rate of T slot aluminum extrusion profiles

- T slot aluminum profile application

- t slot aluminum extrusion

- t slot aluminum framing

- extruded aluminum t slot framing

- t slot aluminum extrusion profile

- Aluminum t slot profile accessories

- Extruded aluminum T slot profile

- T-Slot Profiles

- 6063 T-slot aluminum profiles extrusion

- T-slot frame profile extrusion

- T-slot extrusion profile for protective fences

- What are the classifications of T-slot aluminum profiles extrusion frame

- T-slot aluminum framing

- T slot aluminum extrusion dimensions

- Aluminum t slot framing profile

- T-slot structural framing profiles

- T-slot structural framing

- T slot aluminium extrusion

- Extruded T-Slot Aluminum

- Anodized Aluminium T Slot Profile Extrusion

- T-Slotted Structural Aluminum Profiles

- Customized Aluminum T Slot profiles china

- China T slot shape aluminum profile

- 6063 Industrial aluminum T slot profile

- T slotted aluminum framing

- T slot extruded aluminum profile manufacturer

- 80/20 T slot aluminum profiles

- T bolts and nuts

- Extruded aluminum framing

- Extruding T-slot aluminum profiles china

- Aluminum t-slotted framing extrusion

- T slot aluminum extrusions manufacturers

- Aluminum t-slot extrusion profiles

- Aluminum t slot extrusion

- 40mm t-slot aluminum extrusion

- 20mm x 20mm t-slot aluminum extrusion

- T-slot aluminum extrusion sizes

- 45mm T slot framing

- 6061 Hot Extrusion Aluminum T-Slot Profile

- 6063 Hot Extrusion Aluminum T-Slot Profile

- 6082 Hot Extrusion Aluminum T-Slot Profile

- 6060 Hot Extrusion Aluminum T-Slot Profile

- Aluminum extrusion industrial profile

- Aluminium T-Slot Frame Profile Extrusion

- T-slotted framing rails

- Extruded aluminum t slot extrusion

- 80/20 T-slot Aluminum Building profile

- 15mm extruded aluminum profile

- 16mmT-slot extruded aluminum profile

- 25mm T-slot extruded aluminum profile

- 30mm T-slot aluminum extrusion profile

- 40mm T-slot aluminum extrusion profile

- 45mm T-slot aluminum extrusion profile

- Extruded aluminum t-slot channel

- 40mm T slot framing

- Aluminum T slotted framing rails

- T-slotted extruded aluminum rails

- T slotted aluminum extrusions

- 8080 aluminum extrusion

- Aluminum industrial framing

- Metric t slot aluminum extrusion

- T slot table top aluminum extrusion

- 40x40 aluminium T-slot

- Aluminum square t slot extrusion

- Aluminum extrusion t slot nuts

- Aluminum T-slot structural frames

- Extruded aluminum rail t-slot

- 6060/6061/6082/6063 Aluminum T slotted profiles

- Inside corner gussets for t-slot structural framing

- What are T slot nuts and T-bolt used for?

- T-slot aluminum extrusion profile

- 20x20 aluminum extrusion dimensions

- Aluminium Extrusion Brackets

- Aluminum channel profile t slot

- T-slotted aluminum Extrusion Manufacturer

- 120 mm T-slot aluminum extrusion profile

- 100mm T-slot aluminum extrusion profile

- What are the classifications of T-slot aluminum profiles extrusion frame

- 90 Series T-slot Aluminum Extrusion