Aluminum Extrusion Fence

The T-Slot aluminum profile produced by Henan Chalco is suitable for the production of various safety fences and protective fences, which can be customized according to customer needs, and the delivery is fast and convenient.

Equipment protection fence is to set up protective measures outside the machine and equipment. Partly or completely set up aluminum profile protection fences to ensure the safety of personnel and equipment. Doors or channels are installed in some areas to facilitate the access of goods and personnel.

The safety fence is to divide the equipment or area to protect the equipment and personnel. The aluminum profile safety fence frame uses aluminum profiles, cooperates with various types of plates such as wire mesh, acrylic, pc, etc., and installs expansion bolt connections through aluminum profile accessories. Aluminum profile columns and ground products are safe and stable, easy to disassemble, beautiful and elegant, will not rust, and are maintenance-free for life.

Assembly line fence is to set up protective measures outside the production line. Part or all of the aluminum extrusion fence is established to ensure the safety of personnel and equipment. Doors or channels are installed in some areas to facilitate cargo access and personnel maintenance.

The robot protective fencing is a protective measure applied to the production of robots. A protective measure fence is established outside the working range of the robot to ensure the safety of robot production and personnel. It is generally used in conjunction with various power outages and alarm devices. With the full application and standardization of robot production, the robot protective fence has become an indispensable protective device for the safe production of robots. Robot protective cover, protective fence, protective barrier, colleagues working on the robot to ensure the safety of facilities and equipment and personnel safety, to ensure the smooth progress of work.

Welding enclosure partition contain arc light, heat insulation, blocking welding and splashing sparks, etc. They are mostly used in the field of environmental protection for fume purification and general electric welding work. Aluminum profiles as protective screen brackets are safe and stable, and easy to disassemble.

Workshop enclosure partition is also called fence net, fence, warehouse workshop isolation net is also called mesh partition. The aluminum profile isolation net has the characteristics of simple structure, solid overall, light and beautiful, fast installation speed, and maintenance-free for life. Suitable for all kinds of factories and workshops.

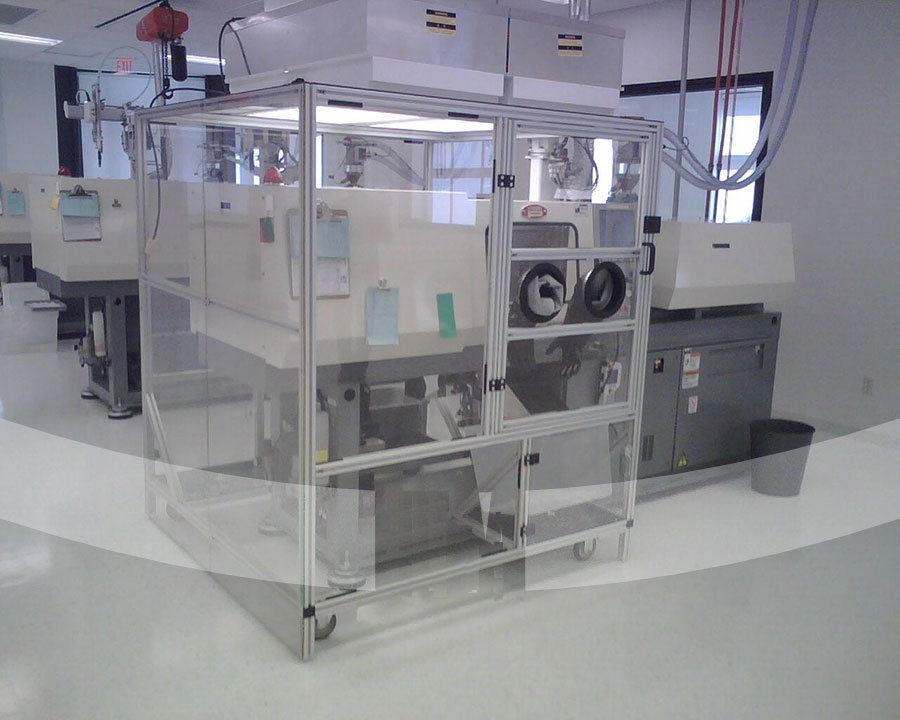

The equipment enclosure zone is a protective cover installed on the equipment to protect the personal safety of the operator in industrial production. The t slot aluminum profile is used as a frame, which is sturdy and durable. When used with barbed wire, the equipment operation can be clearly seen without affecting normal operation.

Equipment protective enclosure are used in industrial production to protect the operator's personal safety and damage to the equipment during material transfer. Various protective covers are installed on mechanical equipment or outside the safe area. The structure and layout of the aluminum profile protective cover are reasonable. The framing part uses aluminum profile with wire mesh, acrylic, pc and other plates, and adopts a closed structure. The surface of the aluminum profile protective cover should be smooth without burrs and sharp edges, which will not affect the sight and normal operation, and is convenient for equipment inspection and maintenance.

The protective cover can strictly prevent dust and chips, hard sand and other particles from entering the track, reduce the damage of the hard granular foreign matter on the sliding track surface, reduce the influence of the guide rail on the machining accuracy due to operation deformation, and maintain the machining accuracy of the machine. The surface of the protective cover should be smooth without burrs and sharp edges and should not become a new source of danger; cutting the protective cover should not affect the sight and normal operation, and should be convenient for equipment inspection and maintenance.