NEWS

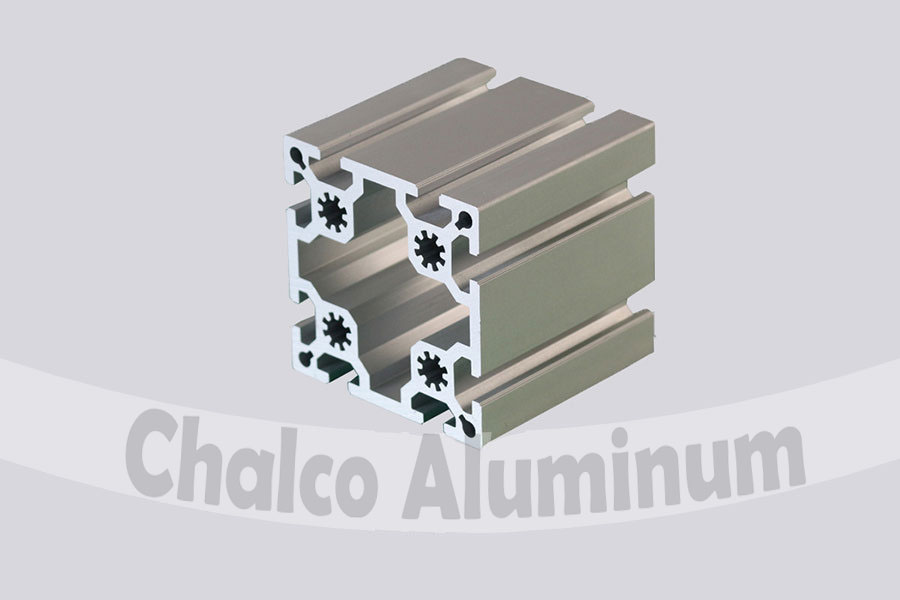

In the production of aluminum and aluminum alloy semi-finished products, extrusion is one of the most important forming technologies, but the operating rate of the corresponding extruder is seriously insufficient. In this situation, it is urgent to improve the production rate of T slot aluminum extrusion profiles. Jiangyin Youwei metal products Co., Ltd. has specific ways to improve the installed level, improve the nature of workers, improve the management level and so on.

For improving the output value of T slot aluminum extrusion products, reliable equipment, high-quality workers and modern scientific management play an important role. First of all, the computer assistant system should be introduced into the T slot aluminum extrusion profile machine to turn and mill the aluminum alloy metal composite parts so that the extrusion time can be shortened as much as possible under the ideal extrusion pressure effect during the isothermal extrusion.

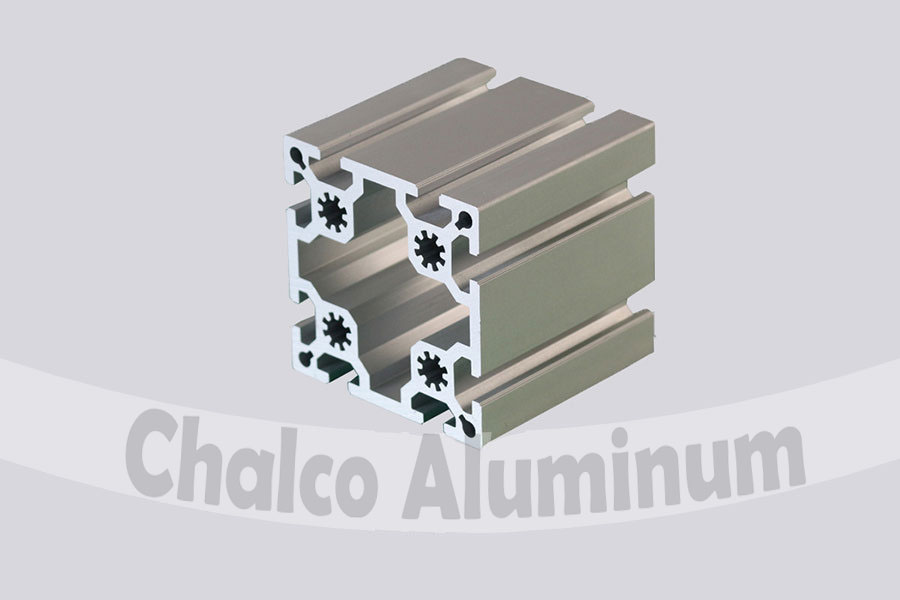

T slot aluminum Extrusion

At the same time, it needs to be equipped with ultra-fine hydraulic oil filter and instruments to continuously monitor the quality and temperature of hydraulic oil. It also needs to be equipped with various technical parameters display and monitoring electronic system to display various information of technical parameters and production status, timely announce the warning and display signals of equipment faults, guide protection and maintenance, and shorten the parking time as much as possible.

It is also very important to pay attention to the temperature increase during preheating, so as to prevent excessive thermal stress between layers. The ideal state is to increase the temperature of extrusion barrel and bushing together to the operating temperature. The preheating and heating speed shall not be greater than 38 ℃ / h; when it is increased to 235 ℃, the temperature is kept for 8h, and the temperature is kept for 430 ℃ for 4h, the operation can be started. In the process of extrusion, the temperature of extrusion barrel should be 15-40 ℃ lower than that of ingot.

The die temperature of T slot aluminum extrusion profile machine plays an important role in achieving high output value, which should not be lower than 430 ℃; on the other hand, it should not be too high. The temperature of ingot can be increased to 40 ℃ or higher in the extrusion process. In order to obtain a larger output value, the temperature of ingot should not be ignored. Each temperature should be recorded and controlled strictly.

NEWS

- What's the T slot aluminum profiles

- Industrial T slot aluminum extrusions

- How to improve the production rate of T slot aluminum extrusion profiles

- T slot aluminum profile application

- t slot aluminum extrusion

- t slot aluminum framing

- extruded aluminum t slot framing

- t slot aluminum extrusion profile

- Aluminum t slot profile accessories

- Extruded aluminum T slot profile

- T-Slot Profiles

- 6063 T-slot aluminum profiles extrusion

- T-slot frame profile extrusion

- T-slot extrusion profile for protective fences

- What are the classifications of T-slot aluminum profiles extrusion frame

- T-slot aluminum framing

- T slot aluminum extrusion dimensions

- Aluminum t slot framing profile

- T-slot structural framing profiles

- T-slot structural framing

- T slot aluminium extrusion

- Extruded T-Slot Aluminum

- Anodized Aluminium T Slot Profile Extrusion

- T-Slotted Structural Aluminum Profiles

- Customized Aluminum T Slot profiles china

- China T slot shape aluminum profile

- 6063 Industrial aluminum T slot profile

- T slotted aluminum framing

- T slot extruded aluminum profile manufacturer

- 80/20 T slot aluminum profiles

- T bolts and nuts

- Extruded aluminum framing

- Extruding T-slot aluminum profiles china

- Aluminum t-slotted framing extrusion

- T slot aluminum extrusions manufacturers

- Aluminum t-slot extrusion profiles

- Aluminum t slot extrusion

- 40mm t-slot aluminum extrusion

- 20mm x 20mm t-slot aluminum extrusion

- T-slot aluminum extrusion sizes

- 45mm T slot framing

- 6061 Hot Extrusion Aluminum T-Slot Profile

- 6063 Hot Extrusion Aluminum T-Slot Profile

- 6082 Hot Extrusion Aluminum T-Slot Profile

- 6060 Hot Extrusion Aluminum T-Slot Profile

- Aluminum extrusion industrial profile

- Aluminium T-Slot Frame Profile Extrusion

- T-slotted framing rails

- Extruded aluminum t slot extrusion

- 80/20 T-slot Aluminum Building profile

- 15mm extruded aluminum profile

- 16mmT-slot extruded aluminum profile

- 25mm T-slot extruded aluminum profile

- 30mm T-slot aluminum extrusion profile

- 40mm T-slot aluminum extrusion profile

- 45mm T-slot aluminum extrusion profile

- Extruded aluminum t-slot channel

- 40mm T slot framing

- Aluminum T slotted framing rails

- T-slotted extruded aluminum rails

- T slotted aluminum extrusions

- 8080 aluminum extrusion

- Aluminum industrial framing

- Metric t slot aluminum extrusion

- T slot table top aluminum extrusion

- 40x40 aluminium T-slot

- Aluminum square t slot extrusion

- Aluminum extrusion t slot nuts

- Aluminum T-slot structural frames

- Extruded aluminum rail t-slot

- 6060/6061/6082/6063 Aluminum T slotted profiles

- Inside corner gussets for t-slot structural framing

- What are T slot nuts and T-bolt used for?

- T-slot aluminum extrusion profile

- 20x20 aluminum extrusion dimensions

- Aluminium Extrusion Brackets

- Aluminum channel profile t slot

- T-slotted aluminum Extrusion Manufacturer

- 120 mm T-slot aluminum extrusion profile

- 100mm T-slot aluminum extrusion profile

- What are the classifications of T-slot aluminum profiles extrusion frame

- 90 Series T-slot Aluminum Extrusion